More

“AICATHLON”–WHAT IS THE BEST WEIGHT CAPACITY OF PLASTIC FOLDING TABLE?

“AICATHLON”–WHAT IS THE BEST WEIGHT CAPACITY OF PLASTIC FOLDING TABLE?

The most important part of manufacturing plastic folding tables is their weight-bearing capacity.While it refers to the amount of weight the table can accommodate, it is also the determinant of a table’s utility level. Many plastic folding tables are not regarded with good weight–bearing capacity, but plastic folding tables from Ai-Cathlon have an impressive feature of heavy-duty for your different needs.

Speaking of the numbers, our residential plastic folding tables can hold more than 330-440lbs even with their lightweight design. Our commercial plastic folding tables are made to accommodate more persons and the table-top load can hold up to 750-1100lbs or more.

Why We Chose Our Technique

Blow molding is the adopted specific technique used by Ai-Cathlon to make long-lasting, quality, and appealing plastic folding tables and chairs. It involves injection blow molding as described in the section above, extrusion blow molding, and stretch blow molding. All these steps come together to make our collection of highly-rated HDPE plastic materials.

But why did we choose this technique? It is a highly cost-effective solution that enables us to produce our products at an affordable rate. It is also easy to do thereby fast-tracking the rates of production. By blow molding molten plastic, we are also able to mold complex parts and incorporate all your tiny requirements into your design.

Our Molding Process

What you see are beautiful, folding, plastic chairs and tables, bistro sets, outdoor sofa pieces that meet the eye, and a hundred more products. But what we see is beauty birthed from our intensive and creative blow molding process. Involved with a series of cutting, bending, molding, laminating, and assembly of many other materials into one, our products are born from scratch and made into museum-worthy artworks. But what is our molding process about?

Blow molding is the top method for plastic material manufacturing and it is also our adopted process. It includes the set-up of the mold that will be used to meet your demands, injection of the molten plastic into the material, actual molding into the shape and design that you want, cooling, and then, releasing.

Material Preparation

We take your requests on the kind of material you want for your order. Though mostly plastic, we put into consideration the color you have chosen, shape, size, and so on. While many of our customers make their pick from our full list of ready-made products, some might like to create their custom orders.

Mold Setup

Next, we set up the mold – making sure to secure in the plates that will give it the structure that makes us top in our field. Then, we fill it with the material you have requested, introduce the clamps, and we’ll be on the way to your accurately created product

Molding

The procedure involves blowing a molten tube until it becomes a hollow object that can be shaped into whatever form you desire. Heat would be applied to the pellets immediately after the injection process starts and that’s when things become fun – at least for us. Once the material is melted, all deformities are eliminated and your piece is taking shape.

Cooling and Release

Cooling comes to ensure that the price is not altered in any way and that your order becomes ready to use.

While there are other methods of manufacturing plastic materials, they are not usually the best choice. Rotational molding, great for short-run productions, might not be the best for your large-scale orders. Molding with gas, the other method, makes the finished product overly light (which is not good for windy days). By adopting the right and best method for plastic material manufacturing, your samples will always be to your taste and will exceed your expectations.

Our Products

Al-Cathlon is often considered one of the top companies in the plastic molding industry. This is because we do not stick to the production of a single service, but multiple products to cover your every need. Using the knowledge of our intensive and effective blow molding process, we build all your products from the get-go till the finished package. Learn more about each product category below;

Plastic Folding Tables

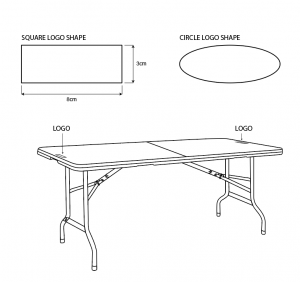

Our folding plastic tables are not your conventional products. Made from only the most-quality slick material, the tables are born. They are made in different designs, shapes, sizes, and colors, depending on your pick for the product. Every table is created from the drafting processing and then brought into our workshop. Assembly and packaging follow right after every metal processing, plastic blow molding, and powder coating. You also get to enjoy colorful differences as birthed in 2013 where we sprayed fashionable, washable, durable colors on our folding plastic tables. Check out a full catalog of our many plastic folding tables

Plastic Folding Chairs

Whether you want a plastic chair that will accompany a conference table, powder-coated with the most impressive materials, or you are in for a commercial folding chair for the garden, camping, picnic, and other outdoor events. Our chairs are made to be convenient, with a lightweight and modern design. Strong and durable, they are also easy to transport. What about the plastic folding bench/chair for outdoor patios? Easy to clean and space-saving, our plastic folding chairs beat the rest in quality and competitive prices. Take a look at our many plastic folding chairs ready for order.

We also have numerous designs for authentic umbrella bases made with heavy-duty HDPE plastic, patio umbrellas made to fit into any aesthetic and outdoor design, and our elastic spandex plastic or polyester table covers to keep your table tops and chairs clean and beautiful.

Who We Are – Our Story

Established in 2006, we have over 15 years of experience making and designing multiple, customer-satisfactory plastic folding tables and chairs. Also highly experienced in the factory business since 2011, our products are made to meet your needs. We pride ourselves to have a grounded reputation in creating quality products and our molding workshop, assembly and packing factory, and other factory plant set-up back that up. Read more about our profession, ambition, creation, and information.

Manufacturing That’s Designed For You!

Though our manufacturing process is highly competitive with the adoption of high-tech, effective injection blow molding processes. Yet, we are also particular about our customer’s satisfaction with every order. That is why we adopted two manufacturing factors that tailor you and your needs to our processes. We adopt OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) to ensure that all our customer’s needs are met in the way they are preferred. Where the latter allows you to our catalog of countless pieces for licensed mass production, the former opens the world to you for creativity.

OEM – Original Equipment Manufacturing

When you choose OEM, you are in charge of what you want and how you want it. We’ll start with a comprehensive, friendly, and detailed inquiry session where you submit all your preferred wants. We also take down your needs during customer’s request, draw our your design, then give you a quotation you would be pleased with. We prepare to mold a sample for you which would be ready in 40 days, give you the sample and wait for your confirmation. Almost too sure you’ll confirm, we prepare an official document that will prompt mass production. A protective and confirmed packaging follows our state quality control policies in order.

ODM – Original Design Manufacturing

Here, we serve you with our numerous design catalogs and you make personalized touches until your order becomes custom-made; just for you. ODM begins with an inquiry session where we get to know what you want and how you want it. Then we begin the friendly and customer-driven negotiation session to confirm your target market, size, and preferred package. After we agree on a quotation, we prepare and give you a sample within 7 days, you confirm, and we process an official order. Mass production commences immediately with your prepared package attached with quality control. Want more information, head on to our OEM/ODM section to learn more about how we strive to meet your needs.

The Team

Behind our catalog of numerous and beautiful products, are our high-skillful and talented team members. Run by several professionally trained workers, we all put our minds into manufacturing unconventional folding tables and chairs, umbrella bases, patio umbrellas, and table covers for your needs.

Our team comprises experts in our heavy-duty plants and factory equipment, professionals in powder-coating, blow molding technicians and workmen, artistic designers, creative minds, and the brains behind the business’s economics. All our processes, from inquiry, to sampling, production, packaging, and shipping are well managed and handled by our very efficient team members on the board for your satisfaction.

Let The Numbers Do The Talking

With 15 years in the business, a 15000sqm factory plant, over 100 trained workers, and multiple awards from over 500 global companies, Ai-Cathlon is a business running with innovation, technology, integrity, and modern innovation. With over 1000 satisfied customers and a full list of catalogs containing over 100 amazing and distinct products, our expertise is much envied around the world.

So what are you waiting for? Join the pack of happy customers and make an order today!