More

Crafting Comfort: The Magic of Injection Molding in Plastic Garden Rattan Sofa Set Production

Crafting Comfort: The Magic of Injection Molding in Plastic Garden Rattan Sofa Set Production

Introduction:

Behind every beautifully designed plastic sofa set lies a carefully orchestrated manufacturing process. At the heart of this process is a technique that borders on magic: injection molding. In this blog post, we’ll take a deep dive into the world of injection molding, the artful process responsible for shaping the components that make up your favorite plastic sofa set.

The Marvel of Injection Molding:

Injection molding is a manufacturing process that transforms raw plastic material into precisely shaped and functional components. It’s the unsung hero behind the sleek lines, comfortable curves, and structural integrity of your plastic sofa set. Let’s demystify the magic:

The Dance of Transformation:

-

Material Selection: Our journey begins with the selection of the right plastic material – be it the sturdy polyethylene (PE) or the versatile polypropylene (PP). This material is carefully chosen for its durability, flexibility, and resistance to various elements.

-

Heating and Melting: The selected plastic material is then heated to its melting point. In a controlled environment, it transforms from a solid state into a viscous, molten form, ready to take on a new shape.

-

Injection into Molds: The molten plastic is injected into molds. These molds are meticulously designed to match the specific components of your sofa set – the frame, the legs, the backrest, the armrests, and more. Each mold represents a piece of the puzzle.

Precision and Artistry:

-

Pressure and Cooling: Once the molten plastic is injected into the molds, it’s subjected to high pressure to ensure it fills every nook and cranny. The molds are also equipped with cooling systems that rapidly solidify the plastic, locking it into its intended shape.

-

Demolding: After the plastic has cooled and solidified, the molds are opened, revealing the newly formed components. It’s a bit like a sculptor unveiling their masterpiece.

The Marriage of Components:

-

Assembly: The freshly molded components are now ready to be assembled. The frame meets the legs, the backrest joins the seat, and the armrests take their place. It’s a carefully choreographed dance of components, each one designed to fit seamlessly with the others.

-

Quality Control: At this stage, the sofa set undergoes rigorous quality checks to ensure that every component meets the highest standards of durability, aesthetics, and functionality.

The End Result: Your Plastic Sofa Set

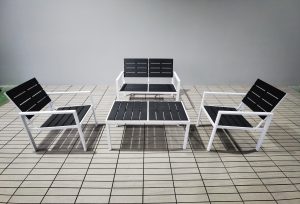

The injection molding process is a testament to human ingenuity and precision engineering. It’s the alchemy that transforms raw plastic material into the beautiful, functional, and comfortable sofa sets that grace our living spaces.

Conclusion:

The next time you sink into the comfort of your plastic sofa set, take a moment to appreciate the journey it embarked on – from carefully selected plastic material to the artful dance of injection molding. It’s a process that marries science and craftsmanship, resulting in furniture that not only serves its purpose but also adds beauty to your home. Injection molding is the magic behind the scenes, making it all possible.