More

Power Unleashed: The Art of Assembling Portable Solar Power Stations

Power Unleashed: The Art of Assembling Portable Solar Power Stations

Introduction:

The journey to create a portable power station, a reliable source of energy for outdoor adventures and emergencies, culminates in the assembly phase. This is where skilled technicians and assembly workers meticulously piece together the components, following exact design and specifications. In this blog post, we’ll unravel the intricate process of assembling portable power stations, where precision meets craftsmanship to bring forth these indispensable power sources.

Assembly: Where Precision Reigns Supreme

-

Blueprint to Reality:

The assembly phase begins with a clear blueprint in hand. Skilled technicians and assembly workers refer to detailed designs and specifications to ensure that every component is placed precisely where it belongs. These blueprints serve as the guiding light, transforming ideas into tangible products.

-

Skilled Workforce:

Assembly is a blend of science and artistry. Skilled technicians, often with years of experience, lead the process. Their expertise ensures that each component is handled with care and precision. This human touch is invaluable in creating reliable power stations.

-

Adhering to Industry Standards:

The assembly process strictly adheres to industry standards and regulations. Quality control measures are in place to verify that every step of assembly complies with safety and performance standards. This commitment to quality guarantees the end product’s reliability.

-

Precise Component Placement:

Components are placed with surgical precision. Engines, alternators, fuel tanks, batteries, and electrical parts are carefully positioned according to the design. This precision is vital to ensure that the generator functions optimally.

-

Wiring and Connections:

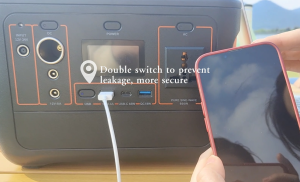

Electrical components are interconnected following the design specifications. Wiring is organized systematically to prevent interference or damage during operation. Connections are secured to prevent loosening or disconnection during use.

-

Testing and Quality Assurance:

Each power station undergoes a battery of tests and quality assurance checks during assembly. These tests include power output checks, fuel efficiency assessments, and noise level measurements. Technicians verify that all safety features, including circuit breakers and voltage regulators, are functioning correctly.

-

Durability and Reliability:

Assembly also includes durability tests. These tests simulate real-world conditions to ensure that the power station can withstand the rigors of outdoor use, from extreme temperatures to physical stress. The goal is to create a generator that stands the test of time.

Conclusion: Precision Meets Craftsmanship

The assembly of portable power stations is a harmonious blend of precision and craftsmanship. Skilled hands and meticulous attention to detail bring forth these reliable power sources that accompany adventurers on their journeys and provide essential energy during emergencies. From the assembly line to the great outdoors, these power stations represent the fusion of human expertise and technological innovation, ensuring that power is always within reach when it’s needed most.