More

Setting in Stone: The Cooling and Solidification Process in Plastic Garden Rattan Sofa Set Production

Setting in Stone: The Cooling and Solidification Process in Plastic Garden Rattan Sofa Set Production

Introduction:

The creation of a plastic sofa set is a carefully choreographed dance of science and craftsmanship. One of the most critical steps in this process is cooling and solidification. In this blog post, we’ll unravel the fascinating world of cooling and solidification, the pivotal moment when the molten plastic transforms into the strong and resilient components that form your beloved sofa.

The Dance of Transformation:

Heating and Injection: Our journey begins with the heating and injection of carefully selected plastic material. This material is transformed from a solid state into a molten form, ready to be shaped.

Mold Magic: The molten plastic is injected into meticulously crafted molds that outline the individual components of your plastic sofa set. The molds are designed with precision to ensure each piece is created to perfection.

The Crucial Role of Cooling and Solidification:

-

Precision Timing: As the molten plastic fills the molds, the clock is ticking. Timing is everything. Once injected, the plastic must be cooled and solidified with utmost precision to retain its intended shape.

-

Cooling Systems: Inside the molds are cooling systems. These can take the form of cooling fans or water channels. Their job is to rapidly cool the plastic, bringing it from a molten state to a solid one.

-

Structural Integrity: The cooling and solidification process is not merely about temperature. It’s about locking the plastic into the right structure. If this is done incorrectly, the components could warp or lose their shape.

Quality Control and Aesthetics:

-

Demolding: After the cooling and solidification process, the molds are carefully opened to reveal the freshly formed components. It’s akin to an artist unveiling a masterpiece.

-

Rigorous Quality Checks: The components then undergo a series of stringent quality checks to ensure they meet the highest standards of quality, aesthetics, and structural integrity.

The End Result: Your Perfect Plastic Sofa Set:

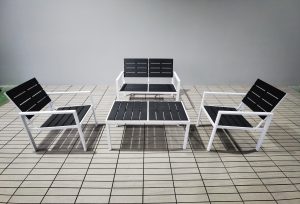

The cooling and solidification process is the bridge between a pool of molten plastic and the stunning sofa set that graces your living space. It’s the science of transforming a liquid into a solid while retaining the elegance and strength that your furniture deserves.

Conclusion:

The cooling and solidification process is where magic and science converge in the creation of plastic sofa sets. It’s a testament to human ingenuity and precision engineering. This process transforms raw material into the beautiful, functional, and comfortable furniture that adds charm and comfort to your home.

So, the next time you relax on your plastic sofa set, take a moment to appreciate the intricate journey it took, from the molten state to structural solidity. It’s a process that combines art and engineering, resulting in furniture that not only serves its purpose but also enhances the beauty of your living space. Cooling and solidification are the keystones in this journey, ensuring your sofa is not just furniture but a work of art.